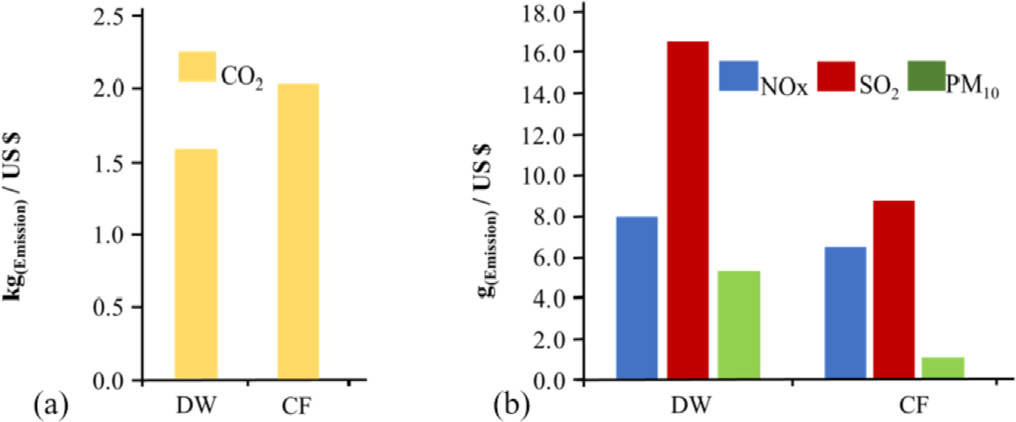

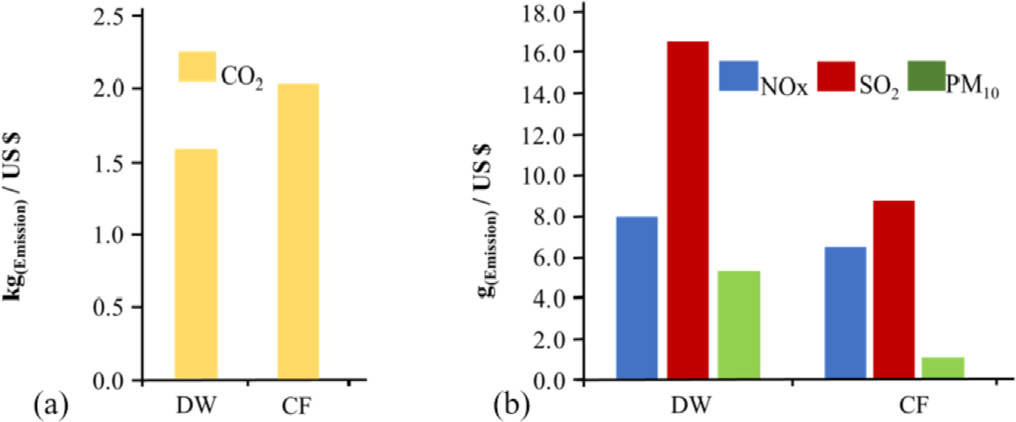

【文章摘要】Strew pellet production not only contribute to regional sustainable development and localized energy transition, but also help to mitigate global greenhouse gas emissions. With the development strew pellet products in China, it is critical to uncover the embodied emissions, land use and economic cost effectiveness from producing strew pellet. In order to reach such a target, two main categories of biomass pellet production including a large-scale centralized factory and a small-scale distributed workshop are investigated. Compared with raw coal production, the unit co-benefits in terms of per gigajoule of straw pellets from centralized factory are 1687 kg CO2, 8.65 g SO2, 3.21 g NOx, and 3.897 g PM10, and 0.33 m2 land use, and those for straw pellets from centralized factory are 1352 kg CO2, 8.46 g SO2, 3.12 g NOx, and 4.22 g PM10, and 0.33 m2 land use. Cost-effectiveness for the two straw pellets production system were also uncovered so that the relevant interested agents such as decision makers, business investors or environmental researchers can see the potential economic performance from developing such kind biomass plants. We conclude that environmental performance of the straw pellets whether from centralized factor or decentralized workshop have attractive alternatives to coal production.

【文章信息】Jiang, L.; Xue, B@; Ma, Z.; Yu, L., Huang, B.; Chen, X. A life-cycle based co-benefits analysis of biomass pellet production in China [J], Renewable Energy, 2020, 154: 445-452. https://doi.org/10.1016/j.renene.2020.03.043

Cost-effectiveness of a distributed workshop and centralized factory